Views: 0 Author: Site Editor Publish Time: 2025-07-21 Origin: Site

You need to cut fiber cement board safely and correctly. Use the right tools for the job and always wear safety gear. Cutting this board makes silica dust. Breathing in this dust can be very harmful to your health:

Silicosis, which is a deadly lung disease

Long-term breathing problems like COPD or emphysema

Lung cancer

Kidney disease

Trouble with how well your lungs work

Work in a place with lots of fresh air. Use ways to control dust, like a vacuum or cutting with water. If you do these things, you can make good cuts and keep yourself safe.

Always wear safety gear like a dust mask, goggles, and gloves. This keeps you safe from dangerous silica dust.

Use the right tools for your project. Use a circular saw with a special blade for thick boards. Use a utility knife for thin boards.

Control dust by working outside. Use a vacuum with a HEPA filter. Keep your workspace clean and let in fresh air.

Mark and measure your cuts carefully. This helps you get straight and accurate edges. It also stops you from wasting materials.

Seal all cut edges with paint or primer. This protects the board from water. It also helps the board last longer.

You need the right tools to cut cement board safely and accurately. Manufacturers often suggest using a circular saw fitted with a carbide-tipped or polycrystalline diamond fiber cement blade. This blade gives you smooth, clean cuts and helps reduce dust. For small jobs, you can use a sharp utility knife to score and snap the board. This method makes less dust but takes more time. Siding shears or snappers work well for straight cuts, especially indoors. If you need to make curves or detailed cuts, a jigsaw or angle grinder with a diamond wheel can help.

Here is a quick guide to the most recommended tools:

Tool Type | Best Use | Safety Tips |

|---|---|---|

Circular Saw | Long, straight cuts | Use dust collection, wear goggles |

Utility Knife | Score and snap for thin boards | Wear gloves, use dust mask |

Siding Shears | Quick, dust-free straight cuts | Good for indoor use |

Jigsaw/Grinder | Curves or small details | Wear eye and dust protection |

You should pick your tool based on the thickness of the board and the type of cut you need. Use a circular saw for thick boards or long cuts. Try the score and snap method for thin sheets or small pieces.

Cutting cement board creates a lot of dust. This dust can harm your lungs. You must wear a dust mask or respirator. NIOSH recommends using a dust-collecting saw connected to a vacuum with a HEPA filter. This setup keeps the air cleaner. Always wear safety goggles to protect your eyes from flying bits. Gloves keep your hands safe from sharp edges. Work gloves with a good grip help you hold the board steady. Try to work outside or in a space with lots of fresh air.

Tip: Use a vacuum with a strong airflow and a short, wide hose for the best dust control.

When you cut cement board, you release tiny silica particles into the air. Breathing in this dust can cause serious lung diseases like silicosis. OSHA says you must use dust collection systems and follow safe work practices. If you use the right tools and wear protective gear, you lower your risk. You also make your workspace safer for everyone. Always check your tools before you start cutting cement board. Make sure your dust collection system works well. Stay alert and protect yourself every time you cut cement board.

You need to control dust before you start cutting fiber cement board. Silica dust can harm your lungs, so you must keep it out of the air. Work outside if you can. Fresh air helps move dust away from your breathing zone. If you must work inside, open windows and use fans to push dust out.

A vacuum dust collection system works best for cutting. Attach a shop vacuum to your circular saw. The saw blade spins fast and moves dust into the collector. The vacuum pulls dust away from the cutting area. This setup can cut airborne silica dust by up to 95%. Field studies show that using a vacuum system keeps dust levels far below safety limits. The design of your saw and vacuum matters. Some blades and collectors work better than others. Always check your equipment before you start.

Tip: Use a HEPA filter in your vacuum. It traps the smallest dust particles and keeps your air cleaner.

Here is a quick checklist for dust control:

Work outdoors if possible

Use a vacuum dust collection system

Wear a dust mask or respirator

Open windows and use fans for airflow

Clean up dust right after cutting

A tidy workspace keeps you safe and helps you work faster. Lay out your fiber cement boards flat on sawhorses or a sturdy table. Keep your tools close but not in your way. Place your saw, vacuum, and measuring tape on one side. Stack extra boards and scraps on the other side.

You can use this table to organize your setup:

Item | Where to Place | Why It Helps |

|---|---|---|

Saw & Vacuum | Dominant hand side | Easy access, safe cuts |

Measuring Tools | Front edge of table | Quick measurements |

Extra Boards | Opposite side | Clear workspace |

Safety Gear | Entry to workspace | Reminds you to gear up |

Keep cords and hoses out of walkways. Sweep up dust and scraps as you go. A clean, organized area helps you avoid trips and mistakes. You stay safer and finish your project faster.

You need to mark your fiber cement board before you cut. Good marking helps you get clean, straight edges. Use a pencil or a fine-tip marker for clear lines. Many professional installers trust the PacTool Aluminum Gable Scribe. This tool lets you measure and transfer any angle from 0° to 90°. It works well for corners and tricky shapes. You can use it instead of several wooden blocks. The aluminum body lasts a long time and stays accurate.

For cutting straight lines, place your board on a flat surface. Hold your measuring tape steady. Mark both ends of the board, then use a straightedge to connect the marks. Double-check your line before you start cutting. If you want to avoid mistakes, measure twice and cut once. This habit saves time and materials.

Tip: Use a bright pencil or marker so you can see your lines even in low light.

You must measure each board before you install it. Accurate measuring keeps your siding even and neat. The Gecko Gauge Fiber Cement Siding Set helps you hold boards in place while you mark them. This tool supports boards up to 12 feet. It also lets you adjust the reveal, so every row lines up perfectly. You can use it to keep your hands free for marking or cutting straight lines.

Follow these steps for best results:

Measure the wall space where you will install the board.

Mark the length on your fiber cement board.

Use the Gecko Gauge to hold the board steady.

Draw your cut line using a straightedge.

A table can help you track your measurements:

Board Number | Length Needed (inches) | Reveal (inches) | Notes |

|---|---|---|---|

1 | 96 | 7 | Starter row |

2 | 94 | 7 | Window trim |

3 | 92 | 7 | Door opening |

Careful marking and measuring help you avoid waste. You get a professional look and save time on every project.

Cutting cement board requires the right techniques and tools. You can choose from several cutting methods, depending on the thickness of the board and the type of cut you need. Each method has its own steps and safety tips. Follow these instructions to cut fiber cement board safely and accurately.

The score and snap method works best for thin fiber cement boards. You should use this technique on boards that are 1/4 inch thick. It does not work well on thicker boards, such as 1/2 inch. When you use this method on 1/4 inch boards, the edges may look ragged, so you may need to smooth them after cutting.

Steps:

Place the board flat on a stable surface.

Use a straightedge to guide your utility knife.

Score the board along your marked line. Press firmly and make several passes.

Move the scored line to the edge of your work surface.

Snap the board downward to break it along the score.

Tip: Always wear gloves and a dust mask when you cut cement board, even with this low-dust method.

You can use this technique for small jobs or when you want to avoid power tools. It creates less dust than saws, but it works only for thin boards.

A circular saw is the most common tool to cut fiber cement board, especially for thick boards or long, straight cuts. You need to choose the right blade for the best results and safety.

Blade Selection:

Carbide-tipped blades with a square-top tooth grind cut efficiently and stay sharp.

Hardened and tempered blades last longer.

Dust reduction designs help keep your workspace clean.

Polycrystalline Diamond (PCD) blades last up to 100 times longer than standard blades.

Thin kerf and deep gullet designs reduce dust and waste.

Premium PCD teeth give you clean cuts and a long blade life.

Non-stick coatings and vibration slots make cutting smoother and safer.

Safety Tips:

Always connect your saw to a vacuum dust collection system.

Wear a respirator and safety goggles.

Work in a well-ventilated area.

Steps:

Place the board on a stable surface, such as sawhorses.

Clamp the board to prevent movement.

Set the blade depth just past the board thickness.

Use a guide rail or straightedge for straight cuts.

Cut slowly and steadily to avoid chipping.

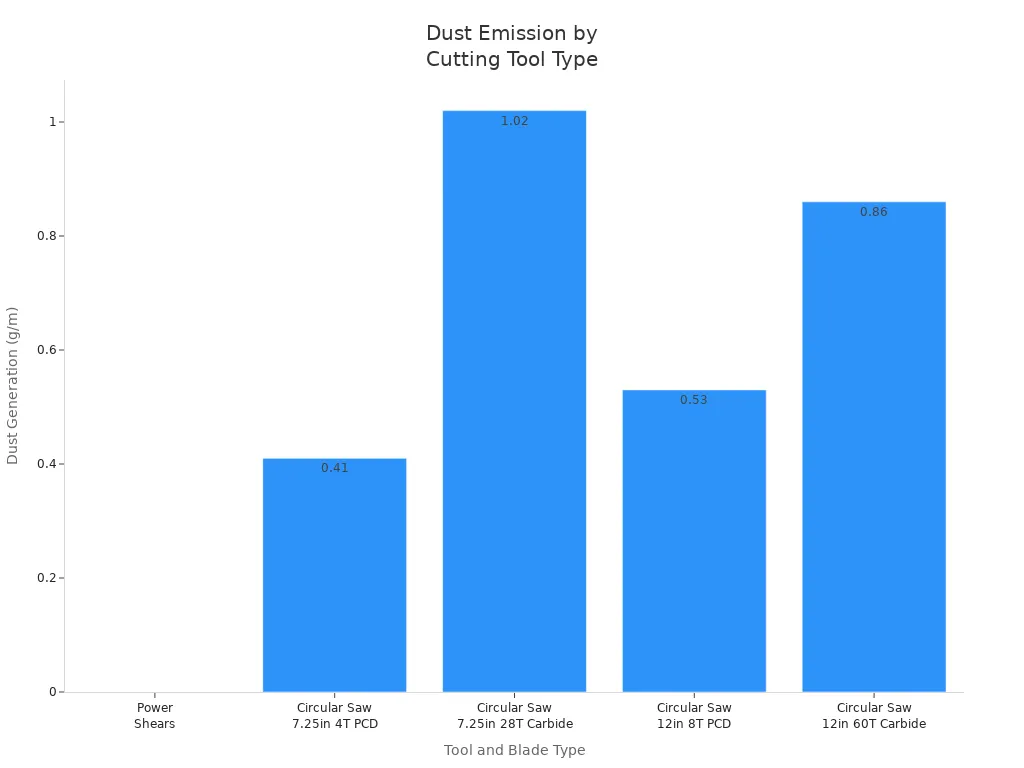

Dust Emission Table:

Tool Type | Blade Diameter (inch) | Number of Teeth | Tooth Type | Respirable Dust Generation Rate (g/m) |

|---|---|---|---|---|

Power Shears | N/A | N/A | N/A | Near zero (almost dust-free) |

Circular Saw | 7.25 | 4 | PCD-tipped | 0.41 ± 0.01 |

Circular Saw | 7.25 | 28 | Carbide-tipped | 1.02 ± 0.04 |

Circular Saw | 12 | 8 | PCD-tipped | 0.53 ± 0.02 |

Circular Saw | 12 | 60 | Carbide-tipped | 0.86 ± 0.03 |

Note: Blades with fewer teeth and PCD tips create less dust. Power shears remain the cleanest option.

Siding shears offer a nearly dust-free way to cut fiber cement siding. You can use them for straight cuts, especially indoors or where dust control matters most. Siding shears make less noise than saws. For example, some models produce only 77 to 82 decibels, much quieter than masonry saws, which can reach up to 110 decibels.

Steps:

Place the board on a stable workbench or sawhorses.

Mark your cut line clearly.

Hold the shears firmly and align them with your mark.

Squeeze the handles to cut along the line.

Siding shears work best for straight cuts. They do not create much dust, so you can use them indoors safely.

When you need to make curved or detailed cuts, using a jigsaw is the best choice. This tool lets you cut fiber cement board for outlets, pipes, or decorative shapes. Always use a fine-toothed blade made for cement board.

Steps:

Secure the board to your work surface with clamps.

Mark the curve or shape you want to cut.

Fit your jigsaw with a carbide-grit or diamond-grit blade.

Start the jigsaw before touching the board.

Guide the blade slowly along your marked line.

Always wear eye protection and a dust mask when using a jigsaw. Work outdoors or use a vacuum to control dust.

Using a jigsaw gives you more control for curves, but it creates more dust than siding shears. You should smooth the edges with a sanding block after cutting.

To cut fiber cement siding, you need to support the board well and use the right techniques. This prevents chipping or breakage and gives you clean results.

Best Practices:

Support the siding on a stable workbench or sawhorses.

Clamp the board to keep it from moving.

Use a carbide-tipped blade designed for fiber cement siding.

Set the saw blade depth just past the board thickness.

Cut at a steady, moderate speed.

Use a guide rail for straight cuts.

For curves, use a jigsaw or scoring knife.

Smooth rough edges with a sanding block.

Check your blade often and replace it if dull.

Take your time for each cut.

You can use these techniques to cut fiber cement siding for windows, doors, or corners. Always follow safety steps and keep your workspace clean.

Tip: Power shears create almost no dust, making them the best choice for indoor jobs or when you want a cleaner workspace.

You now know the main cutting methods for fiber cement board. Choose the right technique for your project, and always use safety gear. Each method helps you cut fiber cement board safely and accurately.

You want your fiber cement board edges to look clean and feel smooth. After cutting, rough edges can make installation harder and let in moisture. Start by using heavy-duty sandpaper. Begin with a grit between 60 and 120. This range works well for removing big bumps and smoothing sharp spots. Indasa Production Sandpaper, known for its high cut power, helps you finish the job quickly. Once you smooth the edge, switch to a finer grit above 120. This step gives the board a polished finish and prepares it for sealing.

Tip: Always wear gloves and a dust mask when sanding. Fine dust can harm your lungs.

After sanding, seal all cut edges. Use paint or primer to keep out moisture. For joints and places where siding meets trim, apply caulk. Choose elastomeric or latex caulking that meets ASTM standards. Paint or prime over caulked areas if needed. This step protects your siding from water damage and keeps it looking new.

Cutting and sanding fiber cement board creates fine dust. This dust contains tiny silica particles that can harm your lungs and pollute the environment. You should never use compressed air to clean up. It blows dust back into the air. Instead, use a shop vacuum with a HEPA filter. This tool traps even the smallest dust particles.

Attach the vacuum to your cutting tools during work.

Use local exhaust ventilation if you work indoors.

Wet down surfaces before sweeping to keep dust from rising.

Wear a respirator if you see dust in the air.

Chemical dust suppressants, like water or salts, can help but may harm soil and water if not chosen carefully. Always pick products that protect both your health and the environment.

Dispose of fiber cement scraps and dust safely. Place all debris in heavy-duty trash bags. Seal the bags before moving them. Never dump dust or slurry into drains or onto the ground. This keeps harmful particles out of water and soil. Take large amounts of waste to a construction debris facility if possible.

Waste Type | Disposal Method | Why It Matters |

|---|---|---|

Dust & Small Debris | Sealed trash bags | Prevents air pollution |

Large Scraps | Construction landfill | Keeps site clean |

Wet Slurry | Solidify, then bag | Protects water sources |

Remember: Safe cleanup protects your health and the environment. Always follow local rules for construction waste.

You need to prepare each board before you install fiber-cement siding. Start by checking every piece for cracks or chips. Lay the boards flat on a clean surface. After you cut a board, coat all cut ends with latex paint right away. This step protects the exposed surface from moisture. Use a brush or roller for quick coverage.

Drill 1/8-inch pilot holes near the edges before you nail the boards. This prevents splitting. Use galvanized or stainless steel nails. Place nails at least 1 inch from the edge. Make sure the nail heads sit snug against the board. Do not drive them too deep. Never nail into the edge or at an angle. For boards around windows, doors, or butt joints, paint the cut ends and caulk where the board meets trim. Caulk helps seal out water and keeps your siding strong.

Tip: Always seal cut edges and caulk joints to prevent moisture problems.

You want your fiber-cement siding installation to last for decades. Follow these best practices to avoid common mistakes:

Leave a 1/8 inch gap where siding meets wood trim or corners. Fill this gap with flexible exterior caulk. This allows for expansion and keeps water out.

Butt joints between siding boards should rest over studs or have flashing behind them. Nail these joints tightly together if flashing is present.

Keep the correct clearance from roofs, patios, and decks. Manufacturers give guidelines for this. It helps prevent trapped moisture.

Use kick-out flashing at gutter ends. This directs water away from the siding and stops hidden damage.

Follow the Evaluation Service Report (ESR) for your product. It gives the right nailing and spacing instructions.

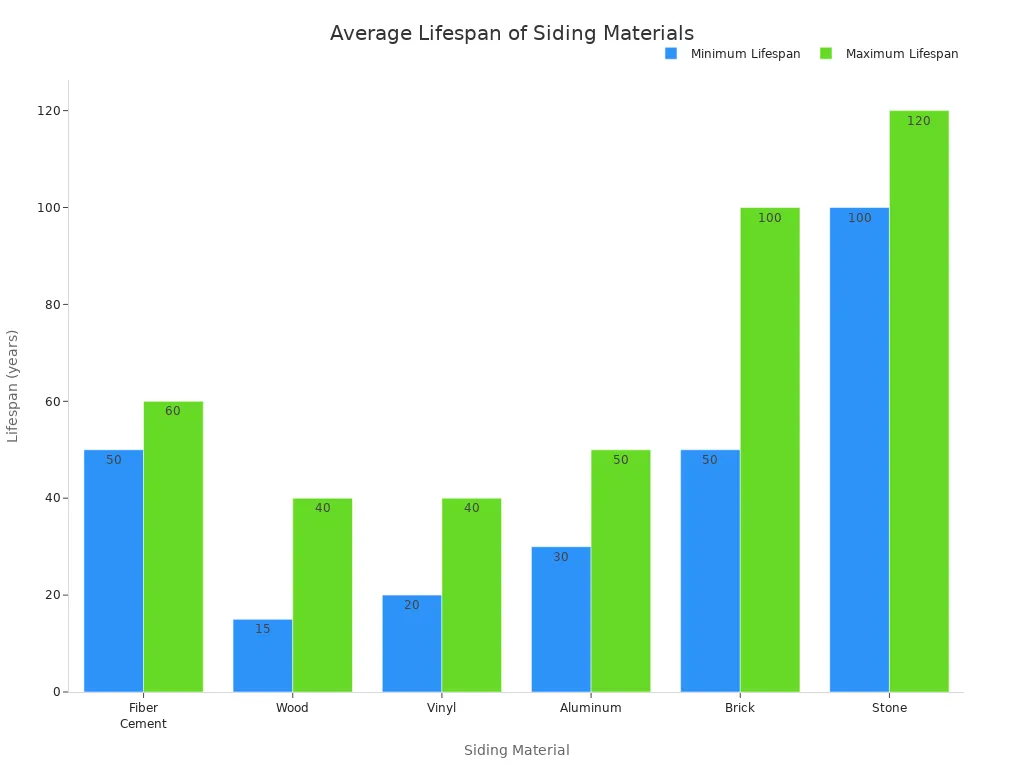

Siding Material | Average Lifespan | Maintenance Needs | Resistance Highlights |

|---|---|---|---|

Fiber Cement | 50+ years (often 60+) | Low | Excellent weather, pest, fire resistance |

Wood | 15–40 years | High | Poor weather and pest resistance |

Vinyl | 20–40 years | Low | Moderate weather resistance, no pest/fire resistance |

Aluminum | 30–50 years | Medium | Moderate weather resistance, some pest/fire resistance |

Brick | 50–100 years | Moderate | Very long-lasting |

Stone | 100+ years | Low | Extremely long-lasting |

You can see that when you install fiber-cement siding correctly, it lasts much longer than wood or vinyl. It resists rot, pests, and fire. You get a strong, low-maintenance finish for your home. Always follow the steps for cement board installation and fiber cement backer board prep to get the best results.

You can cut fiber cement board well if you follow the right steps. Always pick the correct tools and wear safety gear. Cutting this siding makes silica dust, which is very bad for your health. It can cause diseases like silicosis and even lung cancer. You need to control the dust and seal every cut edge to stop water from getting in.

Cutting makes tiny silica dust, which can cause cancer.

Controlling dust keeps you safer and makes work better.

Sealing edges stops swelling and helps the board last longer.

Finishing the edges is quick but makes the board look much better.

Be careful and use these tips. You will have a strong and long-lasting result.

You can cut outdoors to let dust blow away. Attach a vacuum to your saw for better dust control. Use a dust mask or respirator. Wet the board before cutting to keep dust down. Always clean up dust right after you finish.

Choose a polycrystalline diamond (PCD) or carbide-tipped blade. These blades last longer and cut cleaner. Fewer teeth on the blade make less dust. Always check the blade for wear before you start.

You should not use a regular wood blade. It dulls quickly and makes rough cuts. Use a blade made for fiber cement. If you only have a regular saw, use the score and snap method for thin boards.

Yes, you must seal all cut edges. Use paint or primer right after cutting. Sealing keeps out moisture and helps the board last longer. Unsealed edges can swell or crack over time.

Wear a dust mask or respirator, safety goggles, and gloves. Work gloves protect your hands from sharp edges. Always work in a space with good airflow. Use a vacuum with a HEPA filter for extra protection.