Views: 0 Author: Site Editor Publish Time: 2025-07-24 Origin: Site

Yes, you can use fiber cement board on outside walls. Many people pick this material because it is strong and lasts long. It can handle bad weather and is very flexible. It does not break easily and is safe from fire. It also does not need much care. In 2019, 21% of new single-family homes used fiber cement board for outside walls. This shows it is very popular. Not all fiber cement boards are good for outside. You need to pick one made for outdoor use to get the best results.

Fiber cement board is very strong and does not burn easily. It can last more than 50 years. This makes it a good choice for outside walls.

This material does not let in water or bugs. It can handle bad weather. This helps stop mold, rot, and other damage.

Fiber cement board is easy to take care of. You only need to clean it once a year. You should repaint it every 10 to 15 years to keep it nice.

It is important to install it the right way. You need to use the right fasteners and moisture barriers. This stops water damage and helps it last longer.

Fiber cement board gives better value and protection than wood or vinyl siding. It also comes in many styles to match your house.

You want your exterior walls to last for decades. Fiber cement boards give you that peace of mind. When you install and maintain them properly, they can last over 50 to 60 years. This long lifespan comes from their ability to resist moisture, insects, fire, and impact. You do not have to worry about them breaking down quickly like wood or vinyl. Manufacturer warranties often cover 30 years or more for structural integrity. You will find that fiber cement board outlasts wood siding by two to three times and stays stronger than vinyl or aluminum siding.

Fiber cement boards resist water, mold, and wear.

They handle tough weather and do not break easily.

These boards offer impact resistance and keep their strength over time.

Tip: Annual inspections and simple upkeep help you get the most out of your cement board exterior.

You need siding that stands up to all kinds of weather. Fiber cement boards do just that. Lab tests use ultrasound and X-ray methods to check their strength and toughness. These tests show that the boards resist physical and thermal damage. Field tests prove that fiber cement siding can handle floods, extreme heat, and freezing cold. It does not warp or crack like vinyl. FEMA even certifies some products as flood-resistant. Fire resistance tests show a flame spread index of zero, making it a safe choice for wildfire-prone areas.

Fiber cement boards resist moisture, fire, and insects.

They stay stable in hot and cold climates.

Proper sealing and painting keep them safe from moisture and mold.

Unlike wood, they do not rot or attract pests.

You can trust cement board to protect your home from mold, mildew, and pests. The design keeps out termites and stops seams from trapping moisture. This means less risk of mold and mildew compared to other materials.

You want siding that does not need constant care. Fiber cement boards make life easier. You only need to clean them gently and check for damage once a year. Repainting is needed every 10 to 15 years, which is less often than wood. You should trim plants and shrubs to keep them away from the siding. Check caulking around windows and doors each year to stop moisture from getting in. Avoid pressure washing; use soft cleaning methods instead.

Here is a table comparing long-term maintenance costs for common siding types:

Siding Type | Lifespan | Maintenance Needs | Upfront Cost (per sq ft) | Long-term Maintenance Cost |

|---|---|---|---|---|

Fiber Cement | ~50 years | Repaint every 10-15 years | $4 - $15 | Moderate; periodic upkeep |

Stucco | Up to 100 yrs | Regular cleaning | $8 - $14.50 | Lower than fiber cement |

Vinyl | Shorter | More repairs/replacement | $6.50 - $12.50 | Higher due to repairs |

Wood | Shorter | Frequent painting/staining | $1 - $15 | Highest due to upkeep |

Fiber cement boards also help the environment. They use natural materials like sand, cellulose fiber, cement, and water. Many brands recycle old boards and cuttings. Their long lifespan means less waste and fewer replacements. You can even help your building earn LEED certification by choosing this material.

Note: Fiber cement boards are non-combustible and meet the highest fire safety ratings. They work well in wildfire-prone areas.

You can use fiber cement boards for many exterior applications. They work as siding, trim, or accents. Their design keeps your home safe from pests and harsh weather, while also being eco-friendly.

When you compare fiber cement board to wood for exterior walls, you see big differences in strength and care. Fiber cement board stands up to tough weather, pests, and fire. It does not warp, crack, or shrink easily. Wood siding, on the other hand, can fade, rot, or get damaged by insects like termites.

Fiber cement board resists fire, insects, and rot.

It stays strong in storms, hail, and extreme heat or cold.

Wood siding needs regular checks for pests and water damage.

Wood can fade in the sun and needs repainting or staining often.

Here is a quick look at how they compare:

Aspect | Fiber Cement Board | Wood Siding |

|---|---|---|

Installation | Heavier, needs special tools and skilled installers | Lighter, uses standard tools |

Maintenance | Low; wash every 6-12 months, repaint every 10-15 yrs | High; frequent painting, oiling, and inspections |

Durability | Fire, pest, and weather resistant; lasts decades | Prone to rot, insects, and weather damage |

Tip: You save time and money on repairs when you choose fiber cement board for your exterior walls.

Vinyl siding is popular because it costs less and installs quickly. However, fiber cement board lasts much longer and protects your wall better. Vinyl can crack or warp in harsh weather. It also melts in high heat and does not stop fire. Fiber cement board resists fire, water, and pests. It can look like wood or stone, giving you more style choices.

Feature | Fiber Cement Board Siding Panels | Vinyl Siding |

|---|---|---|

Material | Cement, sand, cellulose fibers | PVC plastic resin |

Durability | Highly durable; fire, insect, and rot resistant | Prone to cracking, warping, and melting |

Lifespan | 30-50 years or more | About 20-25 years |

Maintenance | Low; repaint every 10-15 years | Low; no painting, but more repairs |

Environmental | Eco-friendly, recyclable | Less eco-friendly, plastic-based |

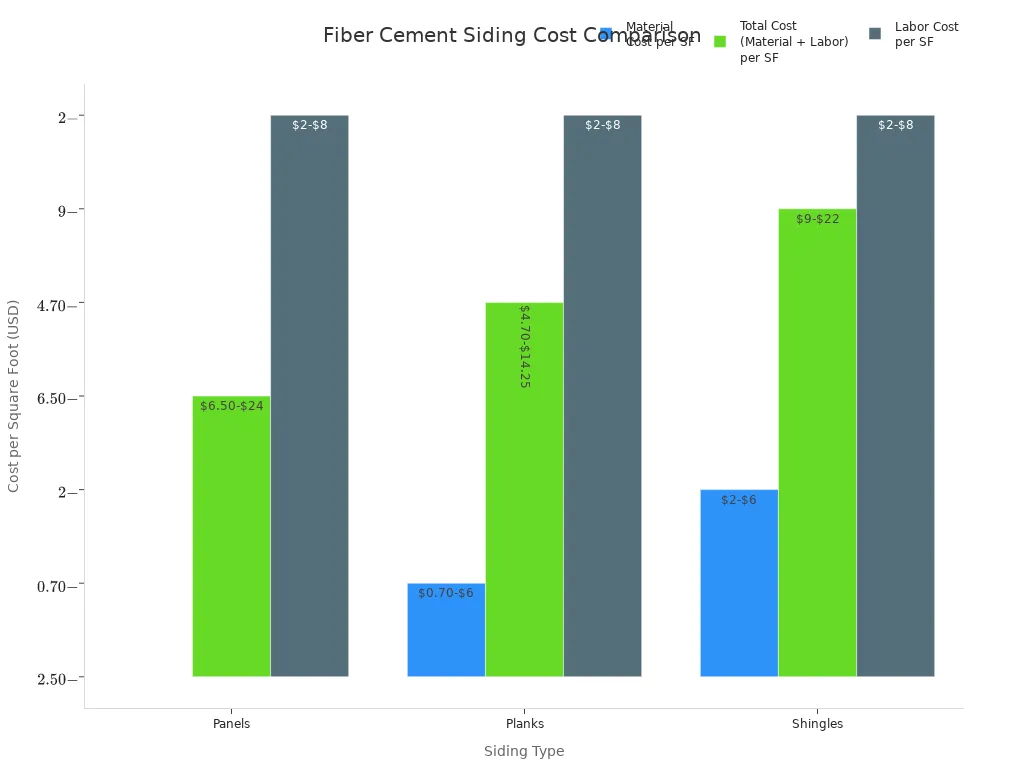

Fiber cement board costs more at first, but you get better value over time. It needs less repair and lasts twice as long as vinyl. Here is a chart showing cost differences:

Stucco and brick both last a long time and resist fire. Brick can last for centuries and needs little care, but it costs more and takes longer to install. Stucco works well in warm, dry places, but it can crack in cold or wet weather. Fiber cement board handles rain, snow, and heat without trouble. It does not crack like stucco or need mortar repairs like brick.

Fiber cement board needs repainting every 10-15 years and simple cleaning.

Brick does not need painting, but mortar joints need checking every few decades.

Stucco may need more repairs if you live in a place with freeze-thaw cycles.

You get strong weather resistance and easy upkeep when you use fiber cement board for exterior walls. It gives you a good balance of cost, looks, and protection.

When selecting fiber cement board for your exterior walls, you need to look for products made for outdoor use. Not all boards work outside. High-density Grade IV panels give you the best strength, especially for tall buildings. You should check for performance types like Type A, which means high performance. Boards come in many colors and textures, so you can match your style. Always make sure the board meets building codes for fire resistance and durability. Some brands offer design help and on-site support, which makes your project easier. Selecting fiber cement board with the right certifications keeps your home safe and helps you get a good warranty.

Here is a table showing what to look for:

Certification/Rating Aspect | Description |

|---|---|

Standard | JG/T 396-2012 for exterior wall boards |

Flexural Strength | Grade I to IV (IV is strongest) |

Fire Resistance | Meets GB 8624-2012 for fire safety |

Waterproof Treatment | Six-sided waterproofing before delivery |

Surface Treatment | Code W (non-painted), Code T (coated) |

Coating | Weatherproof paint as per standards |

You need to follow the right steps to install cement board. Start by using a solid substrate like plywood or OSB. Use corrosion-resistant fasteners, such as 6d or 8d galvanized nails or special cement board screws. For wood studs, nails should go at least 1-1/4 inches deep. For metal studs, use self-drilling screws. Space fasteners 200-300mm apart and keep them 10-15mm from the edge. Pre-drill holes near edges to stop cracking. For tall walls, add extra support like steel reinforcement. Always follow the manufacturer’s instructions for spacing and attachment. Use siding gauges to keep boards straight and even.

Tip: Stainless steel fasteners work best in coastal areas to stop rust.

Many people make mistakes when installing cement board. Here are some to watch out for:

Not measuring carefully before cutting, which wastes material.

Using the wrong fasteners, which weakens the hold.

Failing to stagger seams, which makes the wall less strong.

Skipping proper flashing, which lets water in.

Sealing or painting the board the wrong way, which traps moisture.

To avoid these problems, always double-check your measurements. Use only the fasteners made for cement board. Stagger seams so four corners never meet. Install flashing and keep siding away from patios or metal flashing. Never seal the underside of lap boards. Use the right paint and keep up with caulking. If you skip these steps, you risk water damage, mold, and costly repairs. Selecting fiber cement board with the right features and following these tips helps your exterior walls last longer.

You can use fiber cement boards for many exterior projects. Most people choose them for siding, cladding, and paneling on homes and commercial buildings. Siding made from cement board stands up to weather, pests, and rot. It works well for both modern and traditional styles. You see it in board and batten siding, which adds texture and depth to your wall. Many custom homes, apartments, and hotels use fiber cement boards for their exterior walls. You get many choices in color, finish, and size. This material also helps save energy by providing good insulation. You can mix it with metal, glass, or stone for a unique look.

Fiber cement boards work for siding, cladding, and paneling.

They fit many design styles, from classic to modern.

You can pick from many colors and textures.

Siding made from cement board lasts a long time and needs little care.

You can use cement board for trim and accent features around windows, doors, and corners. It looks like real wood but lasts much longer. You find it in planks, panels, and boards for different trim needs. Cement board trim resists moisture, pests, and fire. It does not warp or crack like wood. You need to know that it is heavier than wood, so it takes more effort to install. When you cut it, use dust control because it makes silica dust. You can expect to repaint trim every 7 to 10 years. Most people find that cement board trim costs less to maintain than wood or stucco.

Tip: Use cement board trim for a wood-like look that stands up to weather and pests.

Fiber cement boards handle tough climates well. They resist freeze-thaw cycles, so you do not see cracks or damage after cold winters. You should install a moisture barrier behind the boards to stop water from reaching the wall. Use corrosion-resistant fasteners to keep the boards secure. In snowy areas, clear snow away from the base of your walls. This stops moisture from causing problems. Choose special product lines for cold or wet climates if you need extra protection.

Follow these steps to keep your siding and trim in top shape:

Clean the boards with a soft brush or hose once a year.

Check for cracks, chips, or peeling paint often.

Repaint every 7 to 15 years, using UV-resistant paint.

Inspect and repair caulking at seams and joints.

Fix any damage right away to protect your wall.

Trim plants near your exterior wall to prevent mold.

Keep gutters clear to stop water from pooling.

You should have a professional install your cement board for the best results. Regular checks and simple care help your siding and trim last for decades.

Fiber cement board helps keep outside walls safe and strong for a long time. It is tough, safe from fire, and easy to care for. Builders like it because it stands up to bad weather, bugs, and mold. You should always pick the right board and follow all the steps to put it in. Here is a simple checklist you can use:

Pick a board made for outside walls.

Make sure it can handle fire and water.

Use fasteners that do not rust.

Put in a barrier to block weather.

Seal and paint the board to protect it more.

Key Factor | Why It Matters |

|---|---|

Durability | Stays strong for many years |

Fire Resistance | Makes your home safer |

Moisture Control | Stops mold and rot |

Easy Maintenance | Saves you time and money |

Versatility | Works in many places and styles |

Yes, you can paint fiber cement board. Use high-quality, exterior-grade acrylic paint. Make sure the surface stays clean and dry before painting. Repainting every 10 to 15 years keeps it looking fresh.

You should always install a moisture barrier behind fiber cement board. This barrier helps stop water from reaching your wall structure. It keeps your home safe from mold and rot.

Use a soft brush or garden hose.

Clean once a year.

Avoid pressure washers.

Remove dirt and mildew with mild soap.

Feature | Fiber Cement Board | Wood Siding |

|---|---|---|

Fire Resistance | ✅ Yes | ❌ No |

Fiber cement board does not burn. It meets top fire safety ratings. You can use it in wildfire zones.