Views: 0 Author: Site Editor Publish Time: 2025-09-17 Origin: Site

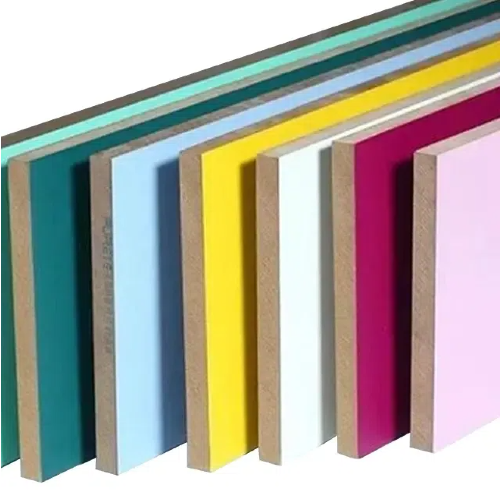

Selecting the right Pre Coated Board is crucial for ensuring both the aesthetic and functional success of any construction or interior design project. With the increasing demand for durable, visually appealing, and low-maintenance materials, Pre Coated Board has become a popular choice across residential, commercial, and public spaces.

However, not all Pre Coated Boards are created equal. Different projects have varying requirements in terms of durability, moisture resistance, fire safety, color, texture, and budget. Choosing the wrong type can lead to premature wear, high maintenance costs, or even project delays. This guide will help you understand the key factors to consider when selecting the ideal Pre Coated Board for your project, ensuring maximum performance, longevity, and design appeal.

Before selecting a Pre Coated Board, it’s important to clearly identify the type of project:

Residential Spaces: Bedrooms, living rooms, kitchens, and bathrooms have unique requirements in terms of moisture resistance, aesthetics, and maintenance.

Commercial Buildings: Offices, hotels, and retail spaces often demand higher durability, resistance to heavy traffic, and professional finishes.

Public Spaces: Hospitals, airports, and educational institutions require boards that meet strict safety, hygiene, and fire regulations.

The environment in which the Pre Coated Board will be installed plays a crucial role in determining the right product:

Indoor Use: Standard boards with moderate durability and aesthetic finishes.

High-Humidity Areas: Kitchens, bathrooms, or laundries require moisture-resistant boards.

High-Traffic Zones: Corridors, commercial lobbies, and public spaces need boards with high scratch and impact resistance.

Your project may have additional functional requirements:

Durability: Ability to withstand wear, scratches, and daily usage.

Moisture Resistance: Important in bathrooms, kitchens, or humid climates.

Fire Resistance: Critical for commercial and public buildings.

Aesthetic Appeal: Color, finish, and texture that match the interior design vision.

Understanding these factors early ensures the board you select aligns with both practical and design objectives.

Pre Coated Boards are available in a wide variety of surface finishes, each suitable for different applications:

Glossy Finish: Reflective, modern, and easy to clean; ideal for kitchens and commercial spaces.

Matte Finish: Elegant, understated look suitable for living rooms and bedrooms.

Textured Finish: Adds depth and visual interest; can mimic natural materials like wood or stone.

Woodgrain Patterns: Provides a warm, natural feel without the maintenance of real wood.

The core of a Pre Coated Board determines its strength and durability:

MDF (Medium-Density Fiberboard): Smooth surface, easy to machine, suitable for furniture and wall panels.

Particleboard: Cost-effective, moderate strength, better for low-traffic areas.

High-Density Composites: Premium option offering superior strength and resistance to warping.

Standard thickness ranges from 8mm to 18mm, depending on the application.

Ensure dimensions match design specifications to minimize cutting waste and ensure structural stability.

Check for waterproof or moisture-resistant certifications if the board will be used in kitchens or bathrooms.

Fire resistance ratings are critical for commercial or public installations to comply with safety standards.

Pre Coated Boards offer a wide palette of colors and textures to match any interior style. Consider:

Consistency: Ensure the color remains uniform across panels to avoid mismatched surfaces.

Harmony with Design: Match the board with furniture, flooring, and lighting for a cohesive look.

Visual Effects: Glossy surfaces reflect light, making spaces feel larger; matte surfaces create warmth and intimacy.

Modern Minimalist: Neutral tones with smooth finishes.

Classic or Traditional: Woodgrain or textured patterns for warmth and sophistication.

Luxury Spaces: High-gloss finishes with metallic or marble effects.

Many suppliers offer custom printing, colors, and textures, allowing boards to align with branding requirements or unique interior concepts.

Choose a board with a durable coating that resists everyday scratches and impacts. High-traffic areas or commercial spaces benefit from boards with enhanced protective layers.

Pre Coated Boards should allow easy cleaning with mild detergents or damp cloths. Avoid abrasive cleaners that can damage the surface or reduce its lifespan.

With proper care, Pre Coated Board can last 10–15 years or more. Selecting boards with enhanced protective coatings ensures durability and reduces maintenance over time.

While Pre Coated Boards may have a higher initial cost than painted walls or wallpapers, they offer:

Reduced Maintenance: Less frequent cleaning and repairs.

Longer Lifespan: Fewer replacements over time.

Time Savings: Quick installation without the need for additional finishing.

Large commercial projects may benefit from bulk purchasing discounts and custom manufacturing options.

Residential projects should balance budget with desired finish and board thickness.

Cost Factor | Pre Coated Board | Painted Walls | Wallpaper | PVC Panels | Tiles |

Initial Material Cost | Moderate | Low | Low | Medium | Medium |

Installation Cost | Low | Moderate | Moderate | Medium | High |

Maintenance Cost (10 years) | Very Low | High | Medium | Medium | Medium |

Replacement Frequency | Low | High | Medium | Medium | Low |

Overall ROI | Excellent | Poor | Fair | Fair | Good |

This table helps illustrate why Pre Coated Board offers a long-term cost-effective solution.

A reputable supplier ensures:

Consistent product quality

Compliance with international standards and certifications

Access to technical support and installation guidance

Look for suppliers who provide:

Custom solutions tailored to project needs

Bulk order options for large-scale projects

After-sales support for warranty claims or maintenance advice

Selecting the right supplier ensures you get boards that meet both performance and aesthetic standards.

Many Pre Coated Boards are manufactured using recyclable materials and low-emission processes, reducing environmental impact.

Low-VOC boards contribute to healthier indoor air quality.

Using eco-friendly boards can support LEED or BREEAM certifications for sustainable construction projects.

Reduces the need for frequent repainting or replacement, minimizing waste.

Contributes to energy efficiency and sustainable building practices.

Sustainability Factor | Pre Coated Board | PVC Panels | Tiles |

Recyclability | High | Low | Medium |

VOC Emissions | Very Low | High | Medium |

Waste Reduction | Strong | Weak | Moderate |

Project Requirements: Environment, traffic, moisture, fire safety

Material Specifications: Surface finish, core quality, thickness, resistance

Aesthetic Goals: Color, texture, style alignment

Durability and Maintenance: Scratch, stain, and water resistance

Budget Constraints: Cost vs. long-term value

Supplier Reliability: Quality, customization, and support

List your project requirements.

Compare board specifications against your needs.

Evaluate supplier options and request samples if needed.

Consider total cost of ownership, including installation and maintenance.

Make an informed selection that balances performance, aesthetics, and budget.

Choosing the right Pre Coated Board involves carefully evaluating your project’s requirements, including material quality, aesthetics, durability, cost, and supplier reliability. By factoring in moisture resistance, scratch protection, maintenance needs, and environmental considerations, you can ensure your investment delivers long-lasting performance and visual appeal.

For projects requiring expert guidance and high-quality materials, Qingdao Leading Intelligent Construction New Material Technology Co., Ltd. provides innovative Pre Coated Board solutions tailored to residential, commercial, and public spaces. Their professional team can assist in selecting the most suitable products, offering technical advice, customization options, and support to guarantee optimal results. Consulting with their specialists ensures your project achieves both sustainability and elegance, making Pre Coated Board a reliable choice for modern, long-lasting interiors.