Views: 0 Author: Site Editor Publish Time: 2025-02-28 Origin: Site

Sustainable construction is an increasingly vital aspect of modern building practices, as the world faces growing environmental challenges and the need for more energy-efficient, eco-friendly structures. Among the materials gaining popularity in sustainable construction, inorganic boards stand out due to their superior performance and environmental benefits. These boards, which are made from non-organic materials such as cement, silica, and other natural minerals, provide numerous advantages for builders, architects, and property owners.

In this article, we will explore the key benefits of using inorganic boards in sustainable construction, discussing their environmental impact, performance characteristics, and overall contribution to the creation of buildings that are more energy-efficient, safer, and longer-lasting.

1. What Are Inorganic Boards?

Inorganic boards are construction materials composed of non-organic substances such as cement, silica, lime, and other mineral-based components. These boards are engineered to offer excellent fire resistance, moisture resistance, and durability, making them ideal for a variety of applications in modern buildings. Unlike organic boards, which are derived from plant or animal matter (such as wood or gypsum), inorganic boards do not degrade over time or release harmful chemicals, offering significant advantages in terms of safety and environmental impact.

Some common types of inorganic boards include:

Calcium silicate boards: Made from a combination of silica, lime, and reinforcing fibers, these boards are widely used for interior and exterior applications due to their excellent fire resistance and moisture control properties.

Fiber cement boards: Made from a mixture of cement, sand, and cellulose fibers, fiber cement boards are versatile, strong, and moisture-resistant, commonly used for cladding, flooring, and interior walls.

Magnesium oxide (MgO) boards: Made from magnesium oxide, these boards are known for their fire resistance, insulation properties, and environmental benefits.

These boards are gaining traction in the construction industry for their ability to enhance the sustainability of buildings and contribute to more energy-efficient and durable structures.

One of the primary reasons inorganic boards are so popular in sustainable construction is their environmental benefits. Here’s a look at how these materials help reduce the environmental footprint of buildings:

Inorganic boards are generally made from abundant, natural materials, which means they require fewer resources to produce compared to other building materials. The manufacturing process for inorganic boards often uses fewer raw materials and less energy, leading to lower carbon emissions and a smaller ecological footprint. Additionally, many inorganic boards can be recycled at the end of their life cycle, reducing the amount of construction waste that ends up in landfills.

Unlike organic materials that may release harmful gases or chemicals as they break down (such as formaldehyde from wood or gypsum), inorganic boards are made from non-toxic substances that do not emit harmful volatile organic compounds (VOCs). This makes them a safer choice for both building occupants and construction workers, contributing to healthier indoor air quality and promoting better overall well-being.

Inorganic boards are incredibly durable, meaning that buildings constructed with these materials will require less maintenance and fewer repairs over time. This reduces the need for replacement materials and the associated environmental costs of manufacturing, transportation, and disposal. For example, fiber cement boards, known for their resistance to moisture, rot, and pests, have a lifespan of several decades, reducing the frequency of repairs or replacements.

Certain types of inorganic boards, such as magnesium oxide boards, are also effective thermal insulators. By improving the energy efficiency of a building, these boards can help reduce heating and cooling costs, which in turn lowers a building’s overall energy consumption. By using inorganic boards in the construction of walls, ceilings, and floors, builders can create more energy-efficient buildings that require less energy to heat or cool, ultimately lowering the building's carbon footprint.

In addition to their environmental benefits, inorganic boards offer a range of performance characteristics that make them an ideal choice for construction projects. These qualities enhance the functionality, safety, and durability of buildings, particularly in areas with demanding conditions.

One of the standout qualities of inorganic boards is their fire resistance. Unlike organic materials such as wood or gypsum, inorganic boards are naturally non-combustible, meaning they do not catch fire or contribute to the spread of flames in the event of a fire. This makes them an excellent choice for enhancing fire safety in buildings, particularly in high-risk areas such as kitchens, basements, and industrial spaces.

Calcium silicate boards and magnesium oxide boards are particularly known for their ability to withstand high temperatures and slow the spread of fire, providing valuable time for occupants to evacuate and for fire services to respond.

In many cases, inorganic boards can be used as part of a building’s fireproofing system to meet stringent fire safety codes and regulations.

Another key benefit of inorganic boards is their moisture resistance. Unlike wood or drywall, which can warp, rot, or degrade when exposed to water, inorganic boards do not absorb moisture. This makes them ideal for use in wet areas such as bathrooms, kitchens, basements, and laundry rooms, as well as exterior cladding that is exposed to the elements.

Fiber cement boards and calcium silicate boards are both excellent at resisting moisture, preventing the growth of mold, mildew, and other moisture-related issues that can compromise the integrity of a building.

In areas where humidity control is a priority (such as in coastal regions), inorganic boards help maintain the structural integrity of buildings and protect them from the damaging effects of moisture.

Inorganic boards also provide sound insulation, which is an important consideration in multi-family buildings, offices, schools, and hospitals. The dense composition of inorganic boards helps to absorb sound, reducing noise transmission between rooms or floors.

Inorganic boards are extremely durable and capable of withstanding harsh conditions. These materials are resistant to weathering, pests, and physical damage, making them suitable for use in both interior and exterior applications.

Given their many advantages, inorganic boards are used in a wide variety of construction applications, contributing to the sustainability of buildings in the following ways:

Inorganic boards are frequently used for exterior cladding in both residential and commercial buildings. Their moisture resistance, durability, and fireproofing capabilities make them an ideal choice for protecting buildings from the elements. Fiber cement boards, in particular, are widely used as an alternative to traditional siding materials such as wood or vinyl, as they offer superior protection from water, termites, and fire.

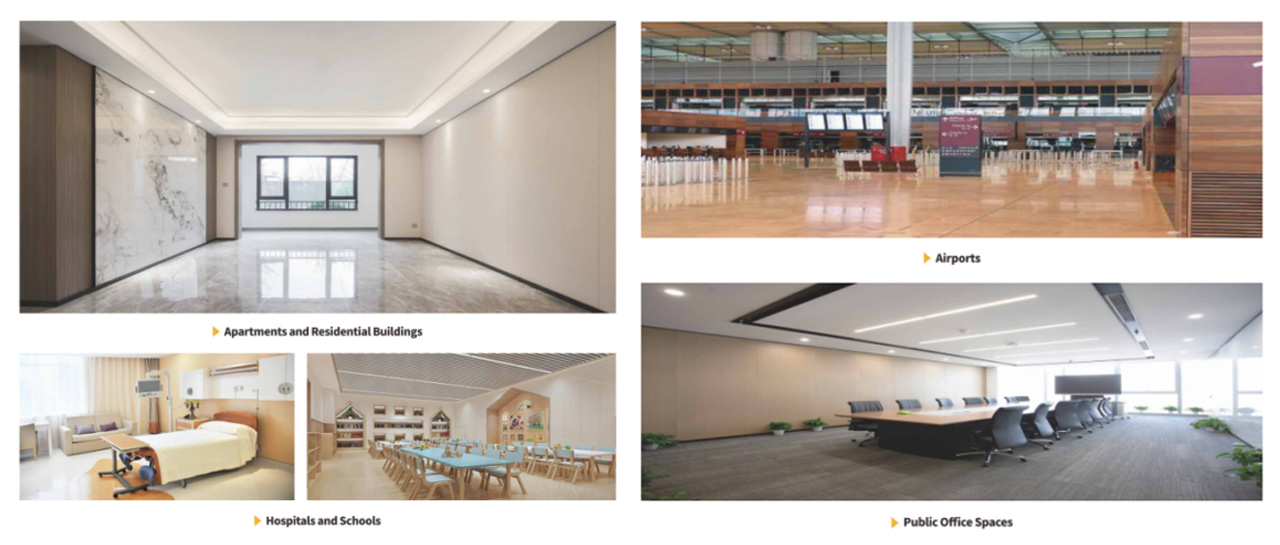

Inorganic boards, such as calcium silicate boards, are often used for interior wall and ceiling applications in areas where moisture resistance and fire safety are critical. For example, these boards are commonly installed in kitchens, bathrooms, and laundry rooms, as well as in high-traffic public spaces like schools and hospitals.

Certain types of inorganic boards, such as fiber cement boards, are also used for flooring in areas prone to moisture. Their strength, resistance to wear and tear, and ability to resist moisture make them ideal for areas like basements and garages, where traditional flooring materials might be vulnerable to water damage.

Inorganic boards are sometimes used in roofing applications due to their fire resistance and durability. Magnesium oxide boards, for example, are often used as a substrate for roofing materials in commercial buildings, providing a strong, fire-resistant base that can withstand extreme temperatures and weather conditions.

Inorganic boards are revolutionizing the way we approach sustainable construction. With their environmental benefits, including low carbon footprints, non-toxic properties, and recyclability, they are helping to reduce the environmental impact of buildings. Their superior performance characteristics, such as fire resistance, moisture control, durability, and sound insulation, make them highly versatile and suitable for a wide range of applications. By choosing inorganic boards, builders can create more sustainable, energy-efficient, and safe buildings that are better equipped to withstand the challenges of modern life.

As the demand for eco-friendly construction materials continues to rise, inorganic boards will play an increasingly important role in shaping the future of sustainable building practices. Whether used for interior walls, exterior cladding, or flooring, these materials offer a reliable and cost-effective solution that aligns with the goals of modern architecture and construction.